The broiler layout farm inculding the following system:

Part 1: The broiler layout farm base-leg-beam-plastic slat floor system:

Part 2:The broiler layout farm automatic nipple drinking line system:

|

Drinking System Parameter |

||||

|

Max Work Length |

150m |

|||

|

Drinking Line Distance |

2.5-3.5m |

|||

|

Nipple Drinking Distance |

20cm/25cm/30cm |

|||

|

Specification |

8nipples/3m, 10nipples/3m, 12nipples/3m, 15 nipples/3m |

|||

|

No. Of Each Nipple Serves |

10-15 birds |

|||

|

Diameter Of Drinking Pipe |

22mm |

|||

|

Hanging Point Distance |

3m |

|||

|

Water Level Display Height |

Chicken day age |

1-7 days |

8-14 days |

More than 15 days |

|

|

Water level height |

50-80mm |

80-200mm |

200-350mm |

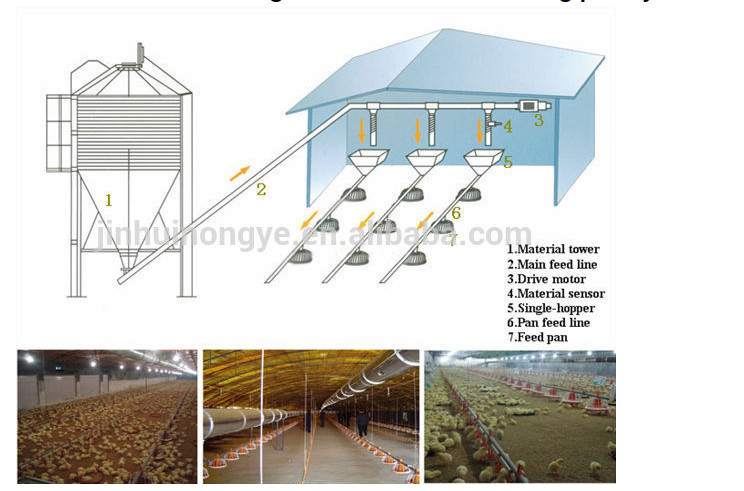

Part 3:The broiler layout farm automatic feeding line system

Part 4:The broiler layout farm environmental control system

Exhaust fan

Cooling pad

This cooling pad can be widely used in Livestock, Poultry farming and Greenhouse.

Frame has two kinds selectable: Aluminum Alloy and Galvanized Steel.

Evaporative cooling pads consist of corrugated sheets of cellulose glued in an opposite sequence, which generates air passage inside the pads. These sheets have very high ability in absorbing water and are chemically treated to prevent disintegration.

Cooling pads are energy saving, environmentally friendly and economically viable as they reduce temperatures without gas emissions and at minimal energy costs with the right controllers, it is possible to keep indoor temperatures within 5 degrees F regardless of external temperature.

Part 5:The broiler layout farm microcomputer controller:

According to temperature and humidity sensor’s signal of ventilation, heating, cooling and others, microcomputer controllerset the parameters in a certain curve to meet requirement of livestock growth.

Part 6:The broiler layout farm manure removal system:

The manureremoval system is mainly used for a variety of sheds and other farming manure cleaning such as the chicken, duck, goat, rabbit and so on. It greatly reduces the labor intensity and maintains good indoor air environment, then provide animals a good living space to reduce the incidence of the disease.

The manure removal system consists of the host seat, corner wheels, traction rope and scraping manure plates. The motor drives the gear work, turn the traction through the wheel to make the scraping manure plates run completed the dung cleaning technology.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)