- Specifications

- Technical Data

- Inquiry

Product name: Piston milking machine for cattle and sheep

Product specifications: single handle milking machine, double handle milking machine

Product Category: For cattle and sheep

Material: metal bracket, stainless steel milk bucket, high-quality motor

Scope of application: for milking cows and sheep

Features:

-1. High-quality stainless steel milk barrel, improve the hygiene of fresh milk, good quality.

-2. Superior performance and high milking efficiency.

-3. It is more convenient to move and reduce the labor intensity of the milker.

-4. Low noise, safe operation and beautiful appearance.

-5. Eliminate the problems of teat bleeding and cows' maladjustment.

-6. Humanized design has no adverse effects on cows and sheep.

Structure: trolley

Simple operation, flexible and convenient, reliable performance, it is an ideal milking equipment essential for small and medium-sized dairy farms and professional dairy farmers to realize modern cow milking.

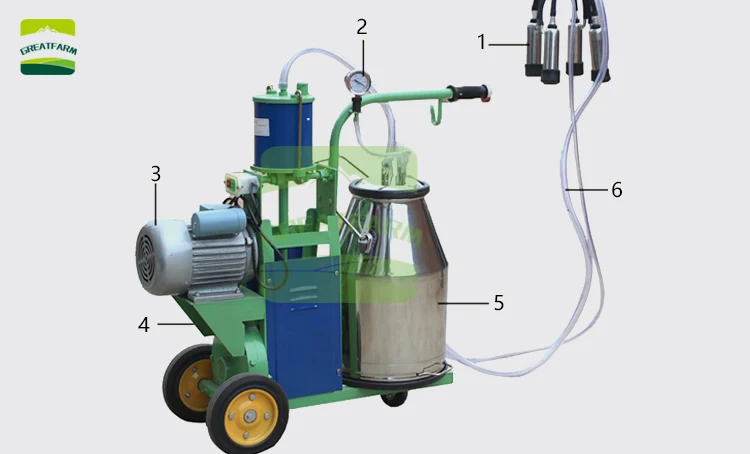

1. Milking device 2. Vacuum meter 3. Motor

4. Support frame 5. Milk tank 6. Pipe

1.High quality stainless steel milk bucket

Stainless steel material, durable, equipped with a lid with a good seal to prevent milk from overflowing, cover with a stainless steel lid after milking, and keep it fresh

2.High quality and low noise motor

Quality assurance, sturdy and durable, easy to maintain, low noise, safer and more worry-free

3. Beautiful and reasonable appearance, easy to move

Make every detail well, the design is strictly designed, it is easy to move.

4.Single handle milking machine for cattle

Double-handle milking machine for cattle and sheep

Milking machine operation process:

1.Before milking, carefully wash and disinfect the milking machine to ensure that the milk is milked to meet the hygienic quality requirements. At the same time, you should observe and touch the appearance of the breasts for redness, heat pain and trauma, and then squeeze the first milk from each breast area into a cup with a net, and check for milk clots, flocs, and water samples. In this way, clinical mastitis can be found in time to prevent mastitis milk from mixing into normal milk.

2. The milking worker must be relatively stable, and at the same time be gentle on the cow, and must not hit the cowt.

3.The teat eraser of the milking machine should have sufficient elasticity and suitable size to suit the use of different sizes of nipples in dairy cows.

4.The milking machine should not have any harmful stimuli to the cows, so as not to affect the health of the cow's breasts and normal milking.

Notes on milking machines:

-1. For cows with small nipples in the first litter, the necessary training and training should be carried out patiently during milking.

-2. When thawing in winter and spring, if the nipples crack, you can apply boric acid ointment after each milking. It is forbidden to use Vaseline to apply nipples.

-3. Cow milk squeezed by cows in the following cases should be treated separately and not for human consumption. One is cow's milk with mastitis (high in bacteria and somatic cells, and a bad smell); the second is cow's milk with ketosis (abnormal taste); and the third is fetal milk and colostrum before delivery.

-4. Be sure to squeeze clean, otherwise it will affect milk production, reduce milk fat rate, and easily cause mastitis and other diseases.

-5. The milking time should not exceed 7 minutes, because the milk completely disappears after 7 minutes. If you pull on the nipples too much, it will irritate the cows no longer to cooperate and cause milking difficulties.

.jpg)

.jpg)

.jpg)